Programming your kiln can be a little intimidating at first but it doesn’t take long before it becomes second nature, like using your microwave. There are a lot of different controllers out there however most have similar functions.

Programming your kiln can be a little intimidating at first but it doesn’t take long before it becomes second nature, like using your microwave. There are a lot of different controllers out there however most have similar functions.

We recommend you follow the programming instructions that came with your kiln. We are including links to the manufacturers websites at the end of this article but we thought it would be helpful to go over some of the basics.

We also recommend that you stick to factory programs whenever possible until you gain a full understanding of your kiln and your craft. As you will find, writing your own programs can get a little complicated.

How Does a Controller Work?

The job of a controller is to control the power of the kiln in such a way that it follows the firing program you have entered. It does this by reading the temperature in the kiln chamber with a thermocouple, which relays the temperature information to the controller. The controller than looks at the information in the program and decides whether it needs to send power to the elements or not.

If it decides it is necessary to send power to the elements, it sends a signal to the relays to close (connecting the power) and power is sent to the elements.

What is a Firing Program?

What is a Firing Program?

Firing programs were developed because bad can happen to your art if you go too fast or too slow through certain temperature ranges. Most hobbyists use factory programs that address these issues. Sometimes you want to fire something that your controllers preset programs are not designed for and therefore you need to write your own programs. An example would be if you wanted to fuse glass in a kiln that is only equipped with factory programs for ceramics. Most controllers used by hobbyists have a programming mode called Ramp and Hold. This is where you would enter your program.

Factory Programs

As you will see in the discussion of Ramp and Hold programs that writing your own programs can be very involved. That is why most kiln manufactures have built in program options that were designed by firing specialists that basically write the programs for you. You just give the controller some basic information and it loads the correct program to run.

ConeFire Mode

ConeFire Mode

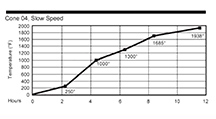

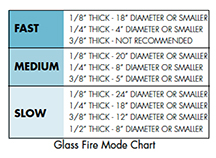

In ceramics, the factory programs are accessed through something called ConeFire Mode. ConeFire Mode can be found on most ceramic controllers offered through kiln manufacturers.

To load a ConeFire program you simply enter a preheat time, the cone value you want to fire to, and a hold time at peak temperature if desired.

The preheat is entered in hours and minutes (i.e. 01.45 would be 1 hour and 45 minutes). A preheat time is recommended if you are not sure if the piece is completely dry. If you place a ceramic piece, especially a large or thick piece, in the kiln that still has moisture in it and fire it too fast, the water left wants to escape as steam and can crack your piece. When you enter a preheat time the program brings up the temperature very slowly and holds it at the time you have entered below boiling point (usually around 180 F). When the preheat time expires, the kiln moves on to the next segment of the program.

The Cone Value you enter can be for a bisque (unglazed clay) firing or a glaze firing. Each clay and glaze has a cone value listed on the box or jar that the manufacture recommends firing to. All you need to do is enter that recommended cone value and press enter.

The firing speed is determined by whether you are doing a bisque fire or a glaze fire. Slow is recommended for bisque fires since there may still be moisture in the piece. Medium is recommended for glaze firings and Fast is only used for specialty items like decals.

Finally, your hold time is generally used to balance out the temperature in the kiln to make sure all of the pieces receive the same amount of heat work. Usually a 5-minute hold is recommended to achieve this. You can also add a little more hold time if to increase the total amount of heat work if your cones were not bending enough.

Finally, your hold time is generally used to balance out the temperature in the kiln to make sure all of the pieces receive the same amount of heat work. Usually a 5-minute hold is recommended to achieve this. You can also add a little more hold time if to increase the total amount of heat work if your cones were not bending enough.

Other Factory Programs

Manufacturers vary on how they present factory programs for glass and metal clay. They are however similar in the sense that they ask a few questions and then have the controller load the appropriate program so you do not have to write or enter it. Consult the manufacturers manual for programming information.

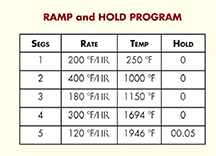

Ramp and Hold Programs

Ramp and Hold Programs

A program consists of one or more program segments strung together. Each segment has 3 pieces of information for the controller to perform; a rate, a temperature and a hold. When the kiln completes the instructions in the first segment it moves on to the next segments until the program is complete.

Rate

The rate, usually expressed in degrees per hour, controls the speed at which the kiln approaches the target temperature. This can be a cooling rate or a heating rate. It is important to remember that the kiln will only perform the best it can to achieve the programmed rate. For example, if you program the kiln to cool at 9999 F/hr it may only be able to cool at 500 F/hr due to heat storage (and because your kiln is not equipped with a refrigeration unit).

In most cases a slower rate is the safer way to go. Problems usually occur when you try to heat or cool too fast.

Temperature

The temperatures you enter can usually be expressed in Fahrenheit or Celsius. When the kiln reaches a temperature in a program it will either hold at that temperature or move instantly to the next segment using a different rate.

It is important to know a little about “heat work” when choosing temperatures in your program. Most of us are familiar with heat work through cooking. Good BBQ is slow cooked for 15 hours at 200 F, but you can attain the same amount of “doneness” by cooking it at 350 F for 2 hours. Heat work refers to the combined affects of time and temperature.

When you are writing your own programs it is important to consider not only the temperature but also the amount of time the kiln took to get to that temperature. The longer the time, the more heat work was achieved.

Hold Times

Hold times can serve several purposes in a program. The first is heat work, which we just discussed. The longer the hold time, the more heat work your pieces in the kiln will be exposed to.

Another useful aspect of hold times is to balance out temperatures in the kiln. Larger kilns have natural hot and cold spots within the kilns chamber. Hold times can help to balance out those differences. A hold time at the end of a firing can allow all the pieces to reach the proper heat work before the kiln begins to cool.

Finally, hold times can be used to balance out the heat within the pieces themselves. For example if you were firing a large glass platter, the rim of the platter which is closest to the elements, may get hotter then the center of the piece if you fire to fast. A hold time inserted in the program every no and then allows the temperatures between the rim and the center of the piece to balance out and prevent the piece from thermal shocking.

Manufacturer Links – Elements

Skutt Video

http://www.skutt.com/video/5_fm_a.firingmode.html